Osmosis is a fundamental phenomenon in nature and also one of the most important technologies in modern water treatment. Understanding the difference between natural osmosis and reverse osmosis helps explain why reverse osmosis is widely used in industrial processes, drinking water production, and desalination.

What Is Natural Osmosis?

Natural osmosis is a physical process that occurs spontaneously in nature. It involves the movement of water through a semipermeable membrane from a solution with a lower concentration of salts or solutes to one with a higher concentration, in order to balance both concentrations. This phenomenon is essential in biological processes such as cell hydration and nutrient transport.

Natural osmosis does not require external energy or specialized equipment. Water movement occurs due to differences in osmotic pressure between two solutions, making it a passive process.

What Is Reverse Osmosis?

Reverse osmosis is a water treatment technology that uses the same principle as natural osmosis but applies it in the opposite direction. By using mechanical pressure, water is forced through a reverse osmosis membrane, which retains dissolved salts, heavy metals, bacteria, viruses, and other contaminants.

This process makes it possible to obtain high-quality water, significantly reducing TDS (total dissolved solids). For this reason, reverse osmosis is widely used in desalination, drinking water purification, water reuse, and critical industrial processes.

Key Differences Between Natural Osmosis and Reverse Osmosis

The main difference lies in the direction of water flow. In natural osmosis, water moves spontaneously to balance concentrations, while in reverse osmosis, pressure is applied to separate water from contaminants.

Another key difference is their application. Natural osmosis occurs in biological and environmental systems, whereas reverse osmosis is a controlled technology designed to ensure water quality, operational efficiency, and regulatory compliance.

Importance in Water Treatment

Reverse osmosis has become one of the most efficient solutions to address water scarcity, reduce operating costs, and ensure a reliable supply in industries such as food and beverage, pharmaceuticals, energy, and manufacturing.

In conclusion, although both processes are based on the same principle, reverse osmosis transforms a natural phenomenon into a key tool for sustainable water treatment.

Today, modern water treatment faces major challenges such as water scarcity, stricter environmental regulations, and a growing demand for high-quality water for industrial, municipal, and commercial use. In this context, filtration membranes have become a key technology to ensure efficient, sustainable, and reliable processes.

Water treatment membranes work as a selective barrier that allows water to pass through while retaining contaminants such as suspended solids, bacteria, viruses, dissolved salts, and organic compounds. Depending on pore size and application, the most commonly used membrane technologies include microfiltration, ultrafiltration, nanofiltration, and reverse osmosis.

One of the main benefits of membrane systems is their high efficiency in contaminant removal without the need for large amounts of chemicals. For example, ultrafiltration is widely used as a pretreatment step to protect reverse osmosis membranes, reducing fouling and extending membrane lifespan, which is critical for lowering operating costs.

Reverse osmosis, in particular, plays a fundamental role in desalination, water reuse, and the production of high-purity drinking water. This technology can remove up to 99% of dissolved salts (TDS), heavy metals, and microorganisms, making it essential in industries such as food and beverage, pharmaceutical, energy, and mining.

Beyond their technical performance, membranes contribute to sustainable water treatment. By optimizing energy consumption, reducing chemical usage, and enabling water reuse, membrane technologies help organizations comply with environmental standards and achieve water efficiency goals.

Another key advantage is process automation and control. Modern membrane filtration systems allow continuous monitoring of parameters such as pressure, flow rate, turbidity, and SDI, ensuring stable operation and consistent water quality.

In conclusion, membranes are a cornerstone of modern water treatment because they offer high efficiency, reliability, and flexibility to adapt to different water sources and applications. Investing in membrane technologies not only improves water quality but also supports operational continuity, cost reduction, and long-term sustainability.

The use of ozone in water treatment has gained significant popularity in industrial, municipal, and commercial applications due to its high water disinfection capability. However, one of the most common questions is whether ozone leaves residues in treated water. Below, we debunk myths and explain the realities behind this technology.

What Is Ozone and How Does It Work in Water

Ozone (O₃) is a powerful oxidizing agent generated on-site from oxygen in the air. In water ozonation systems, ozone eliminates bacteria, viruses, fungi, organic compounds, and unpleasant odors through oxidation, breaking down microbial cell walls and degrading contaminants.

Unlike other disinfectants such as chlorine, ozone acts quickly and more efficiently, even against resistant pathogens.

Myth 1: Ozone Leaves Chemical Residues in Water

False. One of the main advantages of ozone water treatment is that it does not leave chemical residues. Ozone is an unstable molecule that, after performing its disinfecting function, naturally decomposes into oxygen (O₂). This means it does not generate persistent byproducts or alter the taste, odor, or composition of the water.

For this reason, ozone is widely used in the food and beverage industry, drinking water, pharmaceutical processes, and industrial water treatment.

Myth 2: Ozone Is Dangerous for Human Consumption

Partially false. When applied at controlled concentrations and with proper system design, ozone is safe for water treatment. Ozonation systems are engineered to ensure that any residual ozone decomposes before the water is used. In addition, ozone destruction technologies are available to guarantee process safety.

Reality: Ozone Improves Water Quality

Ozone in water treatment not only disinfects but also helps reduce color, turbidity, iron, manganese, and organic compounds, improving the efficiency of downstream processes such as filtration, ultrafiltration, and reverse osmosis.

Reality: A Sustainable Technology

Because it does not generate chemical residues or require the storage of hazardous chemicals, ozone is a solution aligned with sustainability, chemical reduction, and compliance with environmental regulations.

Conclusion

Ozone does not leave residues in water when applied correctly. Far from being a risk, it is a clean, efficient, and safe technology that provides significant benefits in water purification and disinfection, dispelling myths and establishing itself as a reliable solution for industrial and commercial applications.

Water treatment is a critical factor for the proper operation of industrial, commercial, and municipal processes. However, many companies are unsure when it is the right time to consult a water treatment specialist, which can lead to operational issues, higher costs, and regulatory risks. Identifying the warning signs early makes it possible to optimize resources and ensure business continuity.

One of the main situations in which it is advisable to seek a specialist is when there are recurring equipment problems. Issues such as scaling, corrosion, pipe blockages, or frequent failures in boilers and cooling systems are often related to poor water quality or an inadequate treatment system. A specialist can perform a water analysis and determine the root cause of the problem.

It is also recommended to seek expert advice when operating and maintenance costs are high. A poorly designed water treatment system can lead to excessive chemical consumption, higher energy usage, and frequent maintenance shutdowns. A water treatment specialist can propose solutions such as prefiltration, water softeners, reverse osmosis, or process optimization, tailored to the actual needs of the facility.

Another key moment to consult a specialist is during process expansion or modification. Changes in production, increased flow rates, or new applications may require higher water quality or more advanced technologies. Involving an expert during the planning stage helps avoid incorrect investments and ensures that the system meets new operational requirements.

Regulatory compliance is another decisive factor. If a company faces environmental audits, changes in legislation, or difficulties meeting wastewater discharge limits, it is essential to consult a specialist. Proper wastewater treatment and water reuse systems help prevent fines, penalties, and damage to corporate reputation.

Finally, in a context of water scarcity and increasing sustainability demands, working with a specialist makes it possible to implement water efficiency strategies, recycling, and water consumption reduction. These actions not only benefit the environment but also strengthen ESG goals and the company’s competitiveness.

In conclusion, consulting a water treatment specialist is essential when there are operational failures, high costs, process changes, or regulatory challenges. Expert guidance ensures customized solutions, more efficient operations, and safe, sustainable water management in the long term.

Industrial water treatment is a key factor in ensuring a plant’s efficiency, safety, and operational continuity. However, there is no one-size-fits-all solution, as each industrial process requires a specific type of water treatment depending on the quality of the incoming water, its intended use, and the applicable regulations.

The first step in defining the appropriate treatment is water analysis. Water from municipal supplies, wells, or surface sources may contain suspended solids, dissolved salts, hardness, microorganisms, and chemical contaminants. Based on these parameters, the correct combination of technologies is determined to prevent issues such as corrosion, scaling, and equipment fouling.

In processes where water is used for boilers and steam generation, it is essential to implement systems such as prefiltration, water softeners, and, in many cases, reverse osmosis. These treatments reduce hardness and dissolved solids, protecting boilers and improving thermal efficiency.

For plants with cooling towers and refrigeration systems, controlling solids, hardness, and microorganisms is critical. In these cases, multimedia filtration, chemical dosing, and pH control are commonly used, helping to prevent scaling, corrosion, and biological growth while ensuring stable operation.

In industries such as food and beverage, pharmaceuticals, and electronics, where high-purity water is required, advanced technologies such as ultrafiltration, reverse osmosis, and disinfection are used. These systems ensure that water meets strict quality standards to protect the final product and comply with sanitary regulations.

On the other hand, plants seeking to reduce their environmental impact implement wastewater treatment and water reuse systems. Processes such as physical-chemical treatment, biological treatment, and advanced filtration make it possible to recover water for secondary uses, reduce freshwater consumption, and comply with discharge regulations.

In conclusion, the type of water treatment an industrial plant needs depends directly on its process, operational goals, and regulatory requirements. Having a custom-designed water treatment system not only improves water quality but also optimizes costs, protects equipment, and strengthens the long-term sustainability and competitiveness of the industry.

Water softeners are essential equipment in industrial water treatment, as they help reduce water hardness, one of the main issues affecting the efficiency of production processes. Water hardness is primarily related to the presence of calcium and magnesium, minerals that can cause scaling, equipment failures, and high maintenance costs.

In industrial settings, the use of hard water can lead to the formation of calcium scale in piping, boilers, heat exchangers, and cooling towers. These deposits reduce heat transfer efficiency, increase energy consumption, and can cause unplanned shutdowns. Water softeners help prevent these problems by improving operational efficiency and extending equipment service life.

The operation of water softeners is based on the ion exchange process. Through special resins, calcium and magnesium ions are replaced with sodium ions, significantly reducing water hardness. This process is widely used in sectors such as food and beverage, energy, hospitals, pharmaceuticals, and manufacturing, where water quality is critical.

One of the main benefits of industrial water softeners is the reduction of operating costs. By preventing scale formation, the frequency of chemical cleanings, repairs, and corrective maintenance is reduced. In addition, systems that use softened water operate more efficiently, resulting in energy savings and greater process stability.

Water softeners also play a key role as pretreatment for more advanced technologies, such as reverse osmosis and other membrane treatment systems. By reducing hardness, membranes are protected from fouling and their service life is extended, improving the overall performance of the water treatment system.

Another important aspect is regulatory compliance and sustainability. By optimizing water use and reducing the consumption of chemicals and energy, water softeners contribute to more sustainable industrial practices aligned with ESG criteria.

In conclusion, water softeners in industry are not only used to improve water quality, but are also a strategic tool to protect equipment, reduce costs, ensure operational continuity, and improve the efficiency of industrial processes in the long term.

The pH of water is one of the most important parameters in industrial water treatment, as it directly influences process efficiency, equipment lifespan, and regulatory compliance. Understanding what pH is and how it affects operations allows industries to optimize resources, reduce costs, and ensure operational continuity.

pH measures the level of acidity or alkalinity of water on a scale from 0 to 14. A pH of 7 is considered neutral; values below indicate acidity, while higher values indicate alkalinity. In industrial processes, maintaining a controlled water pH is essential, as even small variations can trigger unwanted chemical reactions or affect the quality of the final product.

One of the main impacts of pH in industry is its relationship with corrosion and scaling. A low pH can accelerate corrosion in piping, boilers, heat exchangers, and cooling systems, while a high pH promotes the formation of mineral scale. Both issues increase maintenance costs and can lead to unplanned production shutdowns.

pH control is also critical to the efficiency of water treatment systems, such as reverse osmosis, ultrafiltration, and other membrane treatment processes. A pH outside the recommended range can reduce membrane performance, increase fouling, and shorten membrane lifespan. For this reason, chemical dosing and pH neutralization are often critical stages within the treatment process.

In addition, water pH directly affects wastewater quality. Environmental regulations establish specific pH ranges for the discharge of industrial effluents. Failure to comply with these limits can result in fines, penalties, or operational suspensions, impacting the company’s reputation and financial stability.

In sectors such as food and beverage, pharmaceuticals, chemicals, energy, and manufacturing, pH control is essential to ensure reaction stability, product quality, and process safety. As a result, the use of pH sensors, continuous monitoring systems, and automation is becoming increasingly common.

In conclusion, water pH is not just a technical value, but a strategic factor in industrial processes. Proper pH control ensures more efficient, safe, and sustainable operations, protects equipment, ensures regulatory compliance, and strengthens industrial competitiveness in the long term.

Prefiltration is one of the most important stages in water treatment, as it represents the first step in ensuring efficient, safe, and reliable operation in industrial, commercial, and municipal applications. Its main function is to remove suspended solids, sediments, and particles present in raw water before it enters more advanced treatment processes.

In simple terms, prefiltration consists of a set of filtration systems designed to eliminate physical contaminants such as sand, sludge, oxides, organic matter, and other visible impurities. Water from municipal supplies, wells, or surface sources often contains these types of particles which, if not removed, can cause serious problems in downstream equipment and systems.

One of the main benefits of prefiltration in industrial water treatment is the protection of more sensitive technologies such as reverse osmosis, ultrafiltration, and other membrane treatment systems. When water enters without adequate pretreatment, solids can cause fouling, scaling, and reduced performance, increasing operating and maintenance costs.

Among the most commonly used technologies in the prefiltration stage are multimedia filters, cartridge filters, sand filters, gravel filters, and automatic self-cleaning filters. System selection depends on factors such as water quality, required flow rate, and the type of industrial process. Proper prefiltration design improves overall system efficiency and extends equipment service life.

In addition to protecting infrastructure, prefiltration helps reduce operating costs. By lowering the contaminant load, chemical consumption, cleaning frequency, and maintenance downtime are reduced. This has a positive impact on operational continuity and industrial profitability.

Another key aspect is regulatory compliance. A well-implemented prefiltration system helps ensure that treated water meets environmental and quality regulations, especially when the water will be reused or discharged.

In conclusion, prefiltration is not an optional step, but the foundation of any efficient water treatment system. By removing contaminants at the beginning, the performance of subsequent stages is optimized, equipment is protected, and a more reliable, cost-effective, and sustainable process is ensured in the long term.

Industrial water treatment is a strategic topic that every industrial manager must understand, as it directly impacts operational efficiency, production costs, regulatory compliance, and the company’s sustainability. Although it is often considered a technical matter, understanding its basic concepts enables better decision-making and helps ensure business continuity.

One of the first key concepts is water quality. Water used in industrial processes cannot always be used as it is obtained from the municipal supply, a well, or a surface source. Depending on its composition—dissolved salts, suspended solids, hardness, organic matter, or microorganisms—it can cause issues such as scaling, corrosion, blockages, or equipment failure. For this reason, physicochemical water analysis is the starting point of any water treatment system.

Another essential concept is pretreatment. Technologies such as filtration, the use of filter media, clarification, or chemical dosing make it possible to remove solids, sediments, and contaminants before the water enters critical processes. Proper pretreatment protects equipment such as boilers, cooling towers, heat exchangers, and membrane systems.

In many industries, reverse osmosis and ultrafiltration are widely used technologies. These membrane treatment systems make it possible to obtain high-purity water, which is essential for sensitive processes such as food and beverage production, pharmaceuticals, electronics, and advanced manufacturing. Understanding when and why these technologies are required helps managers evaluate investments strategically.

Water reuse and recycling is another increasingly important concept. Implementing systems that allow wastewater to be recovered and treated reduces freshwater consumption, lowers operating costs, and contributes to achieving sustainability and ESG goals. It also helps mitigate risks associated with water scarcity.

Finally, no industrial manager should overlook regulatory compliance. Environmental regulations require discharged water to meet specific contaminant limits. An efficient water treatment system helps avoid fines, penalties, and operational shutdowns, protecting the company’s reputation and stability.

In conclusion, understanding the basic concepts of water treatment enables industrial managers to make informed decisions, optimize resources, and ensure efficient, safe, and sustainable operations in the long term.

Industrial water treatment has become a fundamental element in ensuring the operational continuity of production processes across different economic sectors. It is not only about complying with environmental regulations such as those governing effluent discharge but about securing an efficient, sustainable, and profitable operation that directly impacts a company’s competitiveness.

First, water treatment ensures that the quality of the water used in internal processes meets the technical standards required by industry. Many industrial activities, from agribusiness to semiconductor manufacturing or chemical production, depend on water with specific purity levels to prevent contamination or failures in their production lines.

A key aspect of operational continuity is the protection of industrial equipment. Untreated water contains minerals, sediments, and other compounds that can cause scaling and corrosion in boilers, heat exchangers, cooling systems, and piping. This type of damage increases equipment wear, accelerates costly repairs, and leads to unplanned shutdowns, which disrupt production and raise operating costs.

In addition to preventing mechanical failures, proper water treatment allows industries to reduce energy and maintenance costs. A well-treated water system improves process efficiency, as pumps and equipment operate with less resistance and consume less energy. It also facilitates water reuse and recycling practices, reducing reliance on external water sources and promoting sustainability.

Another critical point is regulatory compliance. Environmental laws require industries to treat water before discharging it back into natural bodies of water or municipal systems. Failure to comply with these standards can result in fines, penalties, and even temporary shutdowns of operations. For this reason, integrating modern treatment technologies such as membrane filtration, reverse osmosis, or intelligent control systems is a strategic investment that protects business continuity.

Finally, industrial water treatment contributes to sustainability and corporate social responsibility (ESG) goals. Companies that efficiently manage their water resources reduce their environmental impact, strengthen their reputation with customers and stakeholders, and are better prepared to face challenges such as water scarcity and global water stress.

In summary, water treatment is not just a technical or legal obligation, but a strategic tool that ensures operational continuity, efficiency, and long-term resilience for industry.

Today, energy savings are a priority across all industries, and efficient water treatment has become one of the key strategies to achieve this goal. Through optimized water treatment, companies can reduce not only their operating costs but also their environmental impact. Below, we explore how water treatment influences energy savings and the practices that help maximize energy efficiency.

How is water treatment related to energy consumption?

Water treatment is a process that requires a considerable amount of energy, especially in operations involving pumping, filtration, and disinfection. However, when water treatment is inefficient, more energy is needed to properly process the water, and treatment equipment can experience accelerated wear, resulting in higher maintenance and replacement costs.

Implementing an efficient water treatment system can reduce these issues. For example, well-designed reverse osmosis systems can save energy by requiring fewer regeneration cycles and less maintenance, while high-quality filters reduce equipment workload by preventing the buildup of contaminants and solids that may clog the system.

Efficient water treatment practices for energy savings

Several practices and technologies can help reduce energy consumption in water treatment:

Use of advanced membranes:

High-quality membranes require less energy to operate effectively. By using membranes with greater rejection capacity and lower flow resistance, the amount of required pressure is reduced, optimizing energy use in processes such as reverse osmosis.

Energy recovery:

Energy recovery technologies in treatment systems—especially reverse osmosis—can recover up to 50% of the energy. These technologies harness the energy of the wastewater stream and redirect it back into the system, reducing total energy consumption.

Monitoring and automation:

Smart monitoring systems allow operational parameters to be adjusted in real time to maximize efficiency. Sensors that detect variations in water quality and pressure can automatically regulate flow and power, preventing excessive energy use.

Preventive maintenance:

Regular and proper maintenance of treatment equipment reduces the need for excessive energy use. Clean and well-maintained equipment operates more efficiently and consumes fewer resources.

Benefits of efficient water treatment

Energy savings not only reduce operating costs but also decrease carbon emissions, helping companies meet their sustainability goals. Implementing efficient treatment systems also optimizes production by ensuring consistent and reliable water quality. This results in less downtime and longer equipment life, creating a safer and more effective work environment.

In conclusion, efficient water treatment is an investment that, in the long run, reduces energy consumption and operational costs while improving the sustainability of operations.

Water treatment is an essential process to ensure the quality and safety of water, whether for human consumption or industrial use. Two key methods within this process are filtration and disinfection, which serve complementary but distinct functions. Below, we analyze each method and the circumstances in which one may be preferable over the other.

Filtration: A Physical Barrier for Purity

Filtration is a method that uses porous materials or membranes to remove particles and physical contaminants from water. This process is particularly effective at eliminating sediments, clay, sand, and other suspended solids. There are different types of filters, such as activated carbon, sand filters, and ultrafiltration membranes, each designed for specific applications and particle sizes.

One of the main advantages of filtration is its ability to reduce turbidity and improve the taste and odor of water. In industrial environments, filtration is ideal for the pretreatment of wastewater or for initial purification before moving on to disinfection stages. However, filtration alone is not sufficient to remove pathogenic microorganisms such as bacteria and viruses, making it inadequate as a standalone treatment in certain contexts, especially for drinking water.

Disinfection: Eliminating Pathogens

Disinfection is the process used to eliminate or inactivate pathogenic microorganisms that can be hazardous to human health. The most common disinfection methods include the use of chlorine, ozone, and ultraviolet (UV) light. This type of treatment is particularly important in drinking water purification, as it ensures the water is free of bacteria, viruses, and other pathogens that can cause illness.

Each disinfection method has its own advantages. For example, chlorine is effective and long-lasting, allowing water to remain safe during storage and distribution. UV light, on the other hand, is an eco-friendly option that avoids chemical use, making it ideal for applications where environmental protection is a priority. However, disinfection is ineffective at removing physical and chemical contaminants present in water, which is why it is often combined with filtration.

Filtration vs. Disinfection: Which Is the Better Option?

The choice between filtration and disinfection depends on the objective and final use of the water. Filtration is essential for removing particles and suspended solids, improving the appearance and taste of the water, while disinfection ensures microbiological safety. For complete water treatment, both processes are often combined to guarantee both physical and microbiological purity.

Conclusion

Filtration and disinfection are not mutually exclusive methods; in fact, combining both provides the best results in most cases. Filtration removes visible impurities and solids, while disinfection eliminates pathogenic microorganisms. By understanding the capabilities and limitations of each method, industries and users can make informed decisions to ensure water meets the required quality standards.

In reverse osmosis, ultrafiltration, and other membrane technologies for water treatment, one of the most serious problems.

Although mineral scaling and fouling by suspended solids are also significant challenges, microbial growth is considered the number one enemy of membranes because it develops quickly, is difficult to eliminate completely, and generates major operational and economic impacts.

Why is microbial growth so dangerous for membranes?

Biofouling affects water treatment systems on multiple levels:

1. It reduces permeate flow

As the biofilm expands, it clogs the membrane pores, decreasing water production. This is one of the most searched symptoms by operators when investigating “why is my membrane producing less water?”

2. It increases operating pressure

The system needs to work at higher pressure to overcome the resistance caused by attached microorganisms. This means higher energy consumption and increased costs.

3. It promotes corrosion and material degradation

Some bacteria produce acids and compounds that damage the membrane surface and the metallic components of the system.

4. It complicates chemical cleaning

Biofouling is resistant to many traditional chemicals. Biofilms regenerate quickly if cleaning is not performed correctly and with the proper products.

5. It shortens membrane lifespan

It is one of the main reasons operators search for information such as “when to replace a membrane” or “how to extend the life of an RO system.”

How to prevent microbial growth in membrane systems

To avoid this problem, experts recommend:

● Efficient pretreatment

Including filtration, activated carbon, microfiltration, and preliminary disinfection.

● Chlorine and disinfectant control

Removing free chlorine is essential to protect reverse osmosis membranes, but it must be replaced with compatible biocides to maintain microbiological control.

● Scheduled chemical cleanings (CIP)

Using specific products to remove bacteria, enzymes, and biofilms.

● Constant monitoring

Parameters such as SDI, turbidity, microbiological load, and differential pressure should be checked regularly.

Conclusion

Microbial growth not only reduces system efficiency but also increases operating costs and shortens membrane lifespan. For any industry that relies on water treatment, controlling biofouling is key to ensuring continuous operation, permeate quality, and long-term system sustainability.

In water treatment systems, pretreatment for reverse osmosis is one of the most critical steps to ensure that the membranes operate correctly, maintain their service life, and deliver high-quality permeate. The feed water entering the membranes often contains turbidity, suspended solids, colloids, free chlorine, hardness, silica, iron, manganese, and organic matter—contaminants that can cause fouling, scaling, and irreversible damage. Without proper pretreatment, operating costs increase and water production decreases.

For any industry that depends on purified water, investing in proper pretreatment is the best decision to ensure continuity, quality, and long-term performance.

Why is pretreatment indispensable in reverse osmosis?

RO membranes are extremely sensitive to water quality. Even small variations in parameters—such as SDI above 5, free chlorine, or spikes in turbidity—can affect permeability and lead to failures. Key benefits of pretreatment include:

Reduction of suspended solids and turbidity

Prevention of scaling from carbonates, sulfates, and silica

Removal of chlorine to avoid membrane oxidation

Lower risk of biofouling

Increased efficiency and reduced chemical and energy consumption

Extended membrane lifespan

Conclusion

A reverse osmosis system can only operate reliably when the pretreatment is properly designed, adjusted, and monitored. Choosing the right pretreatment not only protects the membranes but also reduces costs, prevents operational downtime, and improves overall process efficiency.

The pharmaceutical industry is critically dependent on water quality. From drug manufacturing to equipment cleaning, every process requires water with strictly controlled physical and chemical characteristics. In this sector, water is not just an input: it is an essential component that impacts product safety, regulatory compliance, and operational efficiency.

Regulations Governing Pharmaceutical Water Quality

To ensure water purity, the industry must comply with international standards such as:

USP (United States Pharmacopeia)

EMA (European Medicines Agency)

WHO – Water for Pharmaceutical Use

These regulations establish strict limits for parameters such as conductivity, TOC (Total Organic Carbon), endotoxins, and microbiological load. Treatment systems must guarantee that the water consistently meets these values.

Key Technologies to Ensure Purified Water and Water for Injection

Treatment plants for the pharmaceutical sector use several advanced technologies. Among the most frequently searched on Google are:

1. Reverse Osmosis (RO)

Removes salts, dissolved solids, microorganisms, and organic matter. It is the core of the system used to produce purified water.

2. Ultrafiltration (UF)

Essential for retaining bacteria, viruses, colloids, and endotoxins. It is fundamental before final disinfection stages or WFI (Water for Injection) production.

3. Electrodeionization (EDI)

Provides high-resistivity water without the use of chemicals, ideal for ultrapure water.

4. Ultraviolet (UV) Light

Helps control bacterial growth and reduces TOC.

5. Sanitary Recirculation Systems

Keep the water in continuous movement to prevent contamination—one of the most common online searches being: “how to prevent biofilm in purified water lines.”

Importance of Continuous Monitoring

Ensuring water quality goes beyond having the best technology. The pharmaceutical industry must implement online monitoring, constant validation, and regular calibration of instruments to ensure parameters remain within specification.

Additionally, CIP/SIP cleaning and thermal or chemical sanitization protocols are vital to preventing microbiological contamination.

Conclusion

Water quality in the pharmaceutical industry is a critical topic that combines technology, regulations, and strict operational controls. Having a robust water treatment system not only ensures regulatory compliance but also protects the integrity of every product. In a sector where purity is essential, investing in advanced water treatment solutions is a strategic and necessary decision.

Water filtration is one of the most important processes in industrial water treatment. Its role is essential to guarantee water quality, protect equipment, optimize operations, and comply with environmental regulations. Today, companies in sectors such as food and beverage, pharmaceuticals, energy, petrochemicals, and manufacturing rely on efficient filtration systems to ensure clean, stable water with the right characteristics for each application.

The growing demand for treated water, along with the need to minimize operating costs, has driven the adoption of industrial filter technologies, membrane filtration systems, sedimentation processes, and advanced filtration as key components of modern operations.

Why is water filtration so important in industry?

Industrial water contains particles, suspended solids, microorganisms, turbidity, and compounds that can affect the efficiency of equipment. Filtration acts as a critical initial barrier in the water purification process, preventing damage to pumps, heat exchangers, boilers, reverse osmosis systems, and production lines.

Key benefits include:

Reduction of sediments and suspended solids

Higher efficiency in downstream processes such as softening, disinfection, and desalination

Extended lifespan of membranes and equipment

Compliance with process water and potable water specifications

Lower energy and chemical consumption

Most widely used filtration technologies

The selection of the system depends on the water type, flow rate, and required quality parameters. The most frequently used technologies include:

1. Sand filtration and granular media

Ideal for removing turbidity, solids, and larger particles. It is one of the most widely adopted solutions due to its low cost and high retention capacity.

2. Cartridge filters and bag filters

Provide fine filtration in micrometric ranges, essential for reverse osmosis pretreatment and high-purity water applications.

3. Ultrafiltration and microfiltration

Membrane processes offering superior removal of microorganisms, colloids, and organic matter.

4. Activated carbon filtration

Fundamental for removing chlorine, odors, tastes, and organic compounds.

An essential component of modern industry

Water filtration is not just a technical stage it is a strategic investment to ensure operational continuity, protect infrastructure, and meet increasingly demanding quality standards.

For any industry seeking efficiency, safety, and sustainability, having an adequate filtration system is the first step toward effective water treatment.

In the world of water treatment, turbidity raises questions such as “what is turbidity?”, “how to measure turbidity,” and “why is it important in drinking water?” Although many parameters influence water quality, turbidity is one of the clearest and fastest indicators of contamination, and a true early warning sign for any industrial, municipal, or commercial process.

What is turbidity and why does it increase?

Turbidity is the measure of suspended particles in water, such as clays, sediments, organic matter, microorganisms, and colloids. It is measured in NTU (Nephelometric Turbidity Units), one of the most popular searches when discussing water quality control.

An increase in turbidity usually indicates:

Changes in the water source, such as heavy rainfall or runoff.

Failures in pretreatment, especially in filtration or flocculation.

Presence of microorganisms, including bacteria and protozoa.

Accidental contamination, due to broken lines or the entry of solids.

Therefore, when turbidity rises, it is a clear sign that something is not working properly.

Turbidity as a critical parameter in industrial processes

In applications such as reverse osmosis, ultrafiltration, boilers, and cooling towers, turbidity not only affects water quality but also equipment performance.

High turbidity increases cleaning frequency, reduces flow, and shortens the service life of membranes.

How to control turbidity efficiently

The most sought-after strategies include:

Multimedia filtration (sand, anthracite, and gravel).

Coagulation and flocculation systems to remove colloids.

Ultrafiltration, the most effective technology when turbidity <1 NTU is required.

Continuous monitoring, another key term in search trends, as it allows real-time detection of variations.

Conclusion

Turbidity is much more than a number: it is a critical indicator and an immediate alarm for the condition of the water. Keeping it under control not only protects equipment, but also human health. In any process, if turbidity rises, it is time to act.

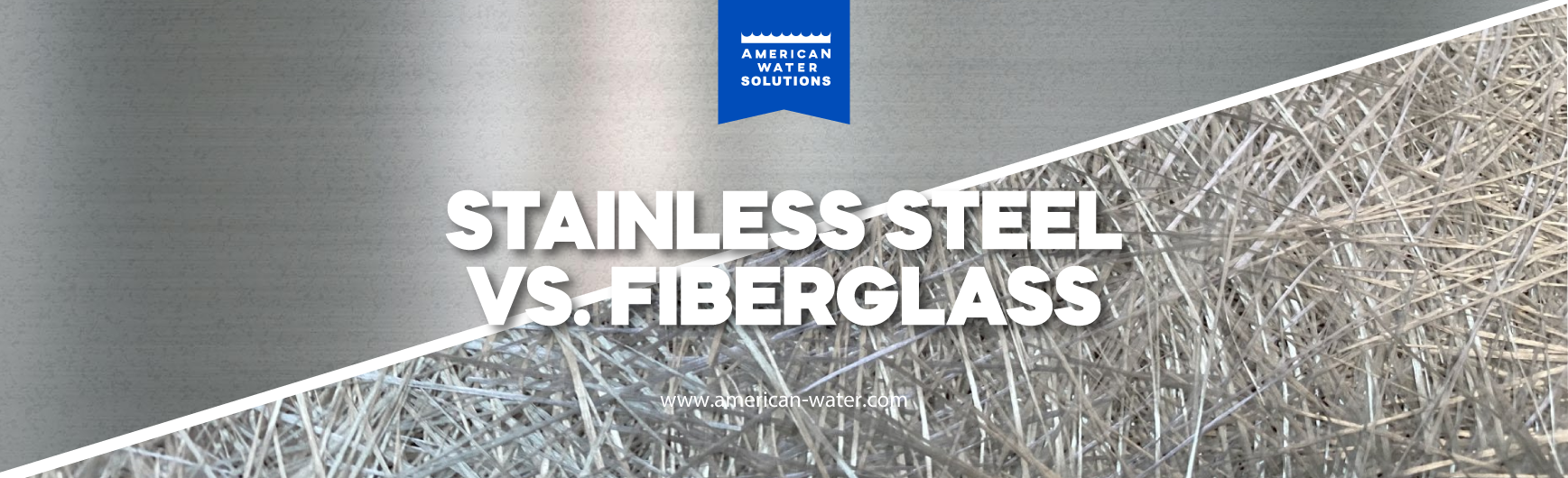

In reverse osmosis (RO) systems, one of the most important components is the membrane holder, as it determines the safety, efficiency, and service life of the equipment.

Stainless steel: extreme resistance and high pressure

Stainless steel is one of the most recommended materials for high-pressure applications, especially in reverse osmosis systems for brackish water or seawater. Its main advantage is its mechanical strength, as it can withstand significantly higher operating pressures than fiberglass. It is also ideal in environments where corrosion is a constant risk, such as desalination plants or industries that use aggressive chemicals.

Its main benefits include:

Excellent tolerance to pressures above 1000 psi.

Longer service life.

High structural strength.

Compatibility with critical applications.

Fiberglass: lightweight, economical, and efficient for standard pressure

Fiberglass (FRP) is the most widely used material in membrane housings for moderate-pressure industrial systems. It is more economical, lightweight, and easier to install than stainless steel, making it ideal for applications such as drinking water, softened water, treated effluents, and low- to medium-pressure RO.

Which one to choose depending on pressure?

Less than 450 psi: fiberglass is the optimal choice.

Between 450 and 1000 psi: it depends on the quality of the FRP, but stainless steel offers greater safety.

Over 1000 psi (seawater): stainless steel, without exception.

Conclusion

The choice between stainless steel and fiberglass should be based primarily on operating pressure, water type, budget, and environmental conditions. Analyzing these factors ensures a safe, durable, and suitable membrane holder for your water treatment system.

Ultrafiltration (UF) has become an essential technology for ensuring safe drinking water in homes, industries, and municipalities. This water treatment process removes microorganisms, suspended particles, and colloidal solids, ensuring that the water we consume is clean, safe, and reliable.

What is Ultrafiltration?

Ultrafiltration is a membrane filtration process that retains nanoparticles, including bacteria, viruses, and protozoa, without relying on harsh chemicals. Unlike conventional filtration, UF acts as a physical barrier, protecting consumer health and maintaining the microbiological integrity of water.

Benefits of Ultrafiltration in Drinking Water

Removal of microbiological contaminants: UF is highly effective against bacteria such as E. coli, Salmonella, and other pathogens that can impact health.

Improved water clarity and taste: By removing suspended solids and turbidity, water becomes clearer and more pleasant to drink.

Reduction of chemical use: Since it does not rely on chemical disinfectants like chlorine to eliminate microorganisms, harmful byproducts are minimized.

Protection of distribution systems: Delivering particle- and microorganism-free water reduces contamination in pipes and storage tanks.

Applications of Ultrafiltration

UF is ideal for municipal treatment plants, food and beverage industries, hospitals, and residential buildings, ensuring safe water for human consumption and critical processes. Its implementation helps comply with water quality standards and ensures operational continuity where water purity is vital.

Considerations for Effective UF

For optimal performance, proper pre-treatment, such as sediment filtration and chlorine control, is essential to protect membranes from damage and extend their lifespan. Additionally, scheduled cleaning and maintenance ensure that ultrafiltration remains effective over time.

Conclusion

Ultrafiltration is not just another water treatment technology—it is a critical tool for safe drinking water. Its ability to remove microorganisms and particles ensures health, trust, and regulatory compliance. Implementing UF systems means investing in a future where the water we consume and use in industrial processes is safer, more reliable, and sustainable.

Reverse osmosis (RO) is one of the most effective technologies for water purification in residential, commercial, and industrial applications. To ensure optimal performance, it is essential to understand the main components of a reverse osmosis system and their role in the process.

1. Pre-filters

Pre-filters are crucial for protecting RO membranes. They typically include sediment filters and activated carbon filters, which remove large particles, chlorine, color, odors, and compounds that could damage the membranes. Proper pre-filtration extends membrane lifespan and enhances overall system efficiency.

2. High-Pressure Pumps

Pressure pumps push water through the semipermeable membranes. This step is critical, as RO relies on pressure to overcome the natural osmotic force and separate contaminants from water. Modern pumps feature control systems that optimize pressure and reduce energy consumption.

3. Reverse Osmosis Membranes

The RO membrane is the heart of the system. These semipermeable membranes allow pure water to pass while retaining salts, heavy metals, microorganisms, and other contaminants. Choosing the right membrane depends on the feed water type and the required purity level.

4. Control Valves and Sensors

Control valves and sensors regulate water flow, pressure, and total dissolved solids (TDS) concentration. These components are critical to prevent system damage, maintain efficiency, and ensure treated water meets quality standards.

5. Storage Tanks and Post-Treatment

Purified water is stored in pressurized tanks before distribution. Some systems also include post-treatment, such as remineralization or UV disinfection, to ensure the final water is safe and high-quality.

Conclusion

Understanding the main components of a reverse osmosis system is key to maintaining safe and purified water. From pre-filters and high-pressure pumps to membranes, control valves, and storage systems, each part plays a vital role in system efficiency and durability. Proper maintenance and performance monitoring ensure your RO system operates optimally, protecting both your investment and water quality.

Filter media are essential components in water treatment systems. Their main function is to remove particles, sediments, chemical contaminants, and microorganisms that affect water quality. However, when filter media do not work properly, they can impact system efficiency, increase maintenance costs, and reduce the lifespan of other equipment. Here are five common reasons why your filter media might be failing.

1. Saturation or Exhaustion of the Filter Media

Over time, filter media such as sand, activated carbon, or ion exchange resins become saturated with contaminants. When this happens, their retention capacity decreases, allowing particles and chemicals to pass into the treated water. Regular monitoring and replacement according to the manufacturer's recommendations are essential to prevent this issue.

2. Inadequate Water Flow

Water flow is a critical factor for the performance of any filter. Excessive flow can cause channeling, where water passes through areas of the media without proper filtration. Conversely, too low a flow can reduce filtration efficiency and increase operating time, leading to higher energy consumption.

3. Biological Contamination

Filter media can also become a breeding ground for bacteria and algae if proper maintenance is not performed. Biofouling in water filters can reduce filtration capacity and compromise water safety. Periodic disinfection and the use of compatible biocides help control this issue.

4. Incorrect Media Selection

Not all filter media are suitable for every type of water or application. For example, granular activated carbon is ideal for removing chlorine, color, and odor, but it does not retain suspended solids. Using the wrong media can cause filtration failures and affect downstream processes such as reverse osmosis.

5. Media Compaction or Wear

Compaction of media such as filter sand can occur due to high pressures or improper backwashing cycles, reducing efficiency. In carbon or resin filters, physical wear can release fine particles, contaminating the treated water.

Conclusion

Maintaining filter media in optimal condition is key to ensuring high-quality water, extending the life of your equipment, and optimizing operational costs. Preventive maintenance, proper media selection, and constant monitoring are the best strategies to avoid failures and ensure efficient water treatment.

Selecting the right tank is a crucial step in any water treatment system, whether for residential, industrial, or commercial use. Choosing the wrong tank can affect efficiency, increase costs, and compromise the quality of treated water. To make an informed decision, it is essential to consider both the tank capacity and the type of water to be stored.

1. Determine the Required Capacity

The tank capacity directly depends on water consumption and the type of system installed. For households, it is recommended to calculate the average daily consumption and add a 20–30% safety margin. In industrial settings, it is critical to know the maximum flow required by the processes, as well as peak demand periods, to ensure a constant supply.

2. Consider the Type of Water

The type of water stored also affects tank selection. Potable water intended for human consumption requires certified, contaminant-free materials, such as stainless steel or food-grade polyethylene. For industrial or process water, tanks made of materials resistant to chemicals or high temperatures may be necessary, depending on the specific process requirements.

3. Tank Material

Various materials are available: plastic, stainless steel, fiberglass, and carbon steel, each with advantages:

Plastic: lightweight, corrosion-resistant, and easy to install.

Stainless steel: durable, hygienic, and suitable for potable water.

Fiberglass: impact-resistant and chemically resistant.

Carbon steel: ideal for robust industrial applications, though it requires anti-corrosion coatings.

4. Design and Maintenance

Tank design is also key. Vertical tanks save space and facilitate water pressure output, while horizontal tanks are easier to transport and maintain. Ensure the tank includes accessible lids, drainage valves, and cleaning systems to simplify routine maintenance.

5. Standards and Certifications

To ensure safety and quality, verify that the tank meets local and international standards, such as NSF or ANSI for potable water. This guarantees no contaminants leach into the water and that the tank withstands operating conditions.

Conclusion

Choosing the right tank not only ensures a reliable water supply but also protects your investment in a water treatment system. Considering capacity, water type, material, design, and certifications is essential to optimize efficiency, reduce maintenance costs, and guarantee water quality at all times.

In water treatment, one of the most important steps to obtain clean, safe, and pleasant water is the removal of chlorine, color, and odor. In this process, granular activated carbon (GAC) has become an essential component thanks to its high adsorption capacity and efficiency in water purification.

What is Granular Activated Carbon?

Granular activated carbon is a porous material with an enormous internal surface area capable of trapping and retaining unwanted molecules. It is produced from organic materials such as coconut shells, bituminous coal, or wood, which undergo a thermal activation process that creates millions of micropores.

These pores act like magnets for organic compounds, free chlorine, pesticides, dyes, and contaminants that affect water quality. Its granular form makes it ideal for fixed-bed filters or continuous treatment systems, ensuring high retention capacity and long service life.

Why is it essential in water treatment?

Granular activated carbon plays a key role in removing residual chlorine, preventing the unpleasant taste and odor often found in drinking water. Moreover, it protects sensitive equipment such as reverse osmosis membranes or ultrafiltration systems from oxidation damage caused by chlorine and other oxidizing agents.

It is also effective in removing volatile organic compounds (VOCs), chlorine by-products, and microcontaminants that could impact both health and industrial processes.

Benefits of Using GAC in Water Treatment Plants

Improves water taste and odor

Protects equipment and membranes

Reduces the formation of toxic by-products

Increases purification system efficiency

Complies with international water quality standards

Conclusion

Granular activated carbon is more than just a filter—it is a strategic ally in any drinking or industrial water treatment system. Its ability to eliminate chlorine, color, and odor makes it an essential step toward achieving higher water quality that is both safe and sustainable.

In a world where water resources are increasingly scarce, water treatment plants have become a key element within the circular economy. This model seeks to keep resources in use for as long as possible, reduce waste, and promote water reuse and energy efficiency in both industrial and urban processes.

Water Reuse: A Pillar of the Circular Economy

Wastewater treatment plants are no longer seen merely as facilities for removing contaminants, but as resource recovery centers. Thanks to advanced technologies such as reverse osmosis, ultrafiltration, and UV disinfection, it is now possible to transform wastewater into reusable water for irrigation, industrial processes, or aquifer recharge.

This approach reduces pressure on natural sources and contributes to water security, an essential concept for long-term sustainability. Moreover, the reuse of treated water lowers operational costs and potable water consumption in sectors such as agriculture, mining, and the food industry.

Toward a Sustainable Future

Embracing the circular water economy is not only an environmental decision but also an economic and strategic one. Companies and industries that implement treatment and water reuse systems enhance their competitiveness, comply with environmental regulations, and strengthen their reputation as responsible players.

Ultimately, water treatment plants are the backbone of a new era of sustainability—one in which water is no longer a waste product, but a renewable resource that drives development and environmental resilience.

Water purification is an essential process in both industrial and residential applications, as it ensures the removal of chemical contaminants, organic matter, and heavy metals. Among the most widely used technologies, activated carbon and ion exchange resins stand out for their efficiency and versatility in drinking water and process water treatment.

Activated Carbon: Effective Adsorption for Cleaner Water

Activated carbon is a porous material with a large internal surface area that allows it to adsorb impurities and organic contaminants from water. Its main function is to remove odor, color, and taste, while also reducing chlorine, pesticides, solvents, and volatile organic compounds (VOCs).

Ion Exchange Resins: Removing Dissolved Salts and Metals

Ion exchange resins are polymers capable of exchanging unwanted ions in water—such as calcium, magnesium, iron, or nitrates—for beneficial ions like sodium or hydrogen.

This process is key to demineralization and water softening, preventing scaling and corrosion in industrial equipment, boilers, and cooling towers.

Resins can be either cationic or anionic, depending on the type of contaminant they remove. In addition, they can be regenerated using chemical solutions, making them a sustainable and long-lasting option.

Conclusion

Activated carbon and ion exchange resins are pillars of modern water purification, combining efficiency, sustainability, and reliability.

While activated carbon removes organic contaminants and improves the sensory quality of water, ion exchange resins ensure the elimination of dissolved salts and metals.

Together, they form an integrated solution for achieving high-purity water—ideal for human consumption, industrial processes, laboratories, and treatment plants.

Access to safe drinking water remains a challenge in many rural communities and areas affected by natural disasters or humanitarian emergencies. In this context, containerized water treatment plants have become an efficient and flexible solution to provide clean water where it is needed most.

What Are Containerized Water Treatment Plants?

These portable modular plants are designed for easy transport and operation anywhere. They integrate advanced technologies such as filtration, UV disinfection, ultrafiltration (UF), and reverse osmosis (RO), allowing for the rapid and reliable treatment of surface, groundwater, or contaminated water.

The main advantage is their mobility and quick installation, making them ideal for remote areas, temporary camps, or emergency response situations. Additionally, their compact design allows for space optimization, making them a practical option compared to traditional large-scale plants.

Benefits for Rural Communities

Containerized plants provide high-quality drinking water to communities lacking advanced water infrastructure. By using multi-stage filtration systems and chemical or UV disinfection, they ensure the removal of bacteria, viruses, sediments, and chemical contaminants.

This not only improves public health but also reduces waterborne diseases. Their simple operation and low maintenance make these plants sustainable and accessible for communities with limited resources.

Use in Emergencies and Disasters

In situations such as floods, earthquakes, or droughts, rapid access to safe water is critical. Containerized plants can be deployed within hours, providing hundreds or thousands of liters of safe water per day. Their modular design allows for capacity adjustment based on demand, ensuring a fast and effective response during emergencies.

Conclusion

Containerized water treatment plants are an essential tool for ensuring safe drinking water in rural communities and emergency scenarios. Their mobility, efficiency, and ease of operation make them the ideal solution to tackle water scarcity and protect public health.

Investing in this technology not only guarantees immediate water supply but also promotes sustainability and community resilience in the face of water challenges.

In water treatment systems, reverse osmosis (RO) and ultrafiltration (UF) membranes are critical components that ensure water purity and process efficiency in both industrial and residential applications. However, these membranes face a silent enemy that can compromise their performance: biofouling and contaminant buildup.

What Damages Membranes the Most?

The primary threats to membranes are microbiological contamination and mineral scaling. When bacteria, algae, fungi, and yeasts adhere to the membrane surface, they begin to form biofilms that obstruct water flow and reduce system efficiency. At the same time, minerals like calcium and magnesium cause scaling, decreasing flow and increasing operating pressure.

Other factors that accelerate membrane wear include:

Excess free chlorine or incompatible chemicals

High turbidity and suspended solids

Sudden changes in pH or temperature

Irregular maintenance or lack of continuous monitoring

Consequences of Not Protecting Membranes

Damaged membranes result in immediate and costly effects: increased TDS (total dissolved solids), reduced flow, higher energy consumption, and more frequent chemical cleanings. This directly impacts the plant’s profitability, water quality, and the lifespan of associated equipment such as pumps, valves, and storage tanks.

Strategies to Protect Your Membranes

Proper pretreatment: Multimedia filtration, water softeners, and ultrafiltration systems help remove solids, sediments, and hardness before they reach the membrane.

Use of biocides and antiscalants: Specialized chemicals control microbial growth and prevent scaling without damaging the membrane.

Continuous monitoring: Measuring parameters like pH, TDS, pressure, and flow ensures early detection of anomalies.

Preventive maintenance: Scheduled membrane cleaning (CIP) and chemical rotation extend lifespan and reduce unplanned downtime.

Conclusion

The biggest enemy of your membranes is the combination of biofouling, scaling, and lack of maintenance. Proper protection through pretreatment, continuous monitoring, and specialized products ensures efficiency, cost savings, and a longer lifespan for your RO and UF systems. In the world of water treatment, prevention is always better than repair.

Reverse osmosis (RO) membranes are the heart of any industrial or residential water treatment system. Their proper functioning ensures pure water, protects your equipment, and optimizes operational costs. However, over time, membranes can degrade, affecting system efficiency. Knowing the key indicators of wear or failure is essential to prevent major problems and ensure uninterrupted processes.

1. Increase in TDS in purified water

One of the most obvious signs that your membranes are deteriorating is an increase in total dissolved solids (TDS) in the treated water. If you notice that the purified water exceeds normal TDS levels, the membrane may have lost rejection capacity, compromising water quality.

2. Reduced water flow

A lower-than-usual flow from your RO system may indicate internal blockages, mineral scaling, or biofouling on the membrane. This problem not only affects water production but also increases pressure in the plant, generating higher energy consumption.

3. Increase in operating pressure

When membranes begin to clog or degrade, the system requires higher pressure to maintain water flow, which translates into increased energy use and premature wear on pumps and valves. Monitoring inlet and outlet pressures can help you identify this issue in time.

4. Changes in taste, odor, or color of the water

If the treated water has a metallic taste, unusual odor, or discoloration, it may indicate that the membrane is no longer effectively removing certain contaminants. This is critical in industries where water purity affects the final product quality, such as food, beverage, and pharmaceuticals.

5. Excessive frequency of chemical cleaning (CIP)

If you find yourself performing chemical cleanings (CIP) more frequently than normal, it is likely that the membrane has reached its operational limit. This not only increases maintenance costs but also reduces the lifespan of associated equipment.

Conclusion

Replacing your reverse osmosis membranes on time ensures safe water, protects your equipment, and maintains energy efficiency. Monitoring parameters like TDS, flow, pressure, and water characteristics allows you to detect signs of wear before they become critical problems. Proactive management guarantees operational continuity, reduces costs, and maintains water quality at the desired standards.

In industrial and municipal water treatment, choosing the right reverse osmosis (RO) membranes is essential to ensure efficiency, energy savings, and water quality. Two of the most popular options are high-rejection membranes and low-energy membranes, each designed to meet different operational and economic goals.

High-Rejection Membranes

High-rejection membranes are designed to remove up to 99% of dissolved solids, including salts, minerals, and chemical contaminants. They are ideal when the priority is achieving maximum water purity, such as in the pharmaceutical, food, or ultrapure water production industries.

Advantages:

High efficiency in removing TDS (total dissolved solids).

Ideal for applications where water quality is critical.

Compatible with processes that require extremely clean water to protect sensitive equipment.

Considerations:

Higher energy consumption due to the pressure required for operation.

Proper pretreatment is necessary to prevent biofouling or scaling on the membrane.

Higher initial investment, although it can be offset by extended membrane life and equipment protection.

Low-Energy Membranes

Low-energy membranes, on the other hand, are designed to minimize electrical consumption and reduce operational costs. They are particularly useful in large plants where energy efficiency is key, and the treated water does not need to be ultrapure.

Advantages:

Lower operating pressure and significant energy savings.

Reduced operational costs without compromising overall system efficiency.

Suitable for industrial applications, such as cooling towers, irrigation systems, or water reuse processes.

Considerations:

Lower TDS rejection compared to high-rejection membranes.

May require additional post-treatment if high-purity water is needed.

Conclusion

The choice between high-rejection membranes and low-energy membranes directly depends on your industrial process requirements, the level of purity needed, and the operational costs you are willing to bear.

In summary, if the priority is ultrapure water and protection of sensitive equipment, high-rejection membranes are the best choice. If the goal is energy efficiency and cost reduction, low-energy membranes provide an optimal balance between performance and savings. Evaluating parameters such as TDS, operating pressure, energy consumption, and type of application will ensure your water treatment system operates efficiently and sustainably over the long term.

Brine management is one of the most important challenges in water desalination and treatment. Brine is the concentrated byproduct left after processes such as reverse osmosis (RO) or evaporation desalination, and its proper handling is crucial to protect the environment and optimize the efficiency of water treatment systems.

Why Brine Management Matters

Brine contains high concentrations of salts and minerals, and its indiscriminate discharge can affect aquatic ecosystems, increase the salinity in rivers and seas, and damage nearby agricultural soils. Therefore, the water industry seeks sustainable strategies for its disposal and treatment, ensuring compliance with environmental regulations and operational sustainability.

Sustainable Management Strategies

Controlled dilution and safe discharge: A common practice is to dilute brine with treated water before releasing it into receiving bodies. This minimizes environmental impact and helps meet water quality standards.

Recirculation and reuse: Brine can be reused in industrial processes that tolerate high salt concentrations, such as chemical manufacturing or irrigation of salt-tolerant crops.

Evaporation and crystallization: Some systems allow valuable salt recovery from brine through evaporators or crystallizers, generating useful byproducts and reducing waste.

Pre-treatment and post-treatment technologies: Integrating ultrafiltration, nanofiltration, and advanced reverse osmosis reduces dissolved solids concentration, making brine management safer and more efficient.

Benefits of Sustainable Brine Management

Environmental protection: Reduces water pollution and protects local biodiversity.

Regulatory compliance: Ensures operations meet strict environmental standards.

Economic efficiency: Reusing or valorizing brine can generate savings and new revenue for the industry.

Operational sustainability: Guarantees that water treatment processes are responsible and viable long-term.

Conclusion

Sustainable brine management is not only an environmental requirement but also an opportunity for innovation in the water treatment industry. Implementing intelligent strategies for disposal, reuse, and recovery helps minimize negative impacts, optimize resources, and contribute to a more sustainable and efficient future in water management.

Seawater desalination has become a key solution in addressing global water scarcity. However, one of the main challenges of this technology is the high energy consumption associated with the process, especially in reverse osmosis (RO) systems. This is where energy recovery plays a crucial role, increasing efficiency and reducing operational costs.

What is Energy Recovery in Desalination?

Energy recovery involves capturing and reusing the energy contained in the concentrate or brine flow of the desalination process. In a reverse osmosis system, the reject water has significant pressure, and through energy recovery devices, such as pressure exchangers or turbines, that pressure is converted into usable energy to power the system, reducing the need for additional electrical energy.

Key Benefits

Reduction of energy costs: Energy recovery systems can reduce up to 40% of total energy consumption in desalination plants, making the process more cost-effective and sustainable.

Improved operational efficiency: By utilizing the residual pressure of the reject water, the efficiency of water flow through membranes is enhanced, optimizing the production of potable or process water.

Environmental sustainability: Desalination without energy recovery leads to higher carbon emissions due to electricity consumption. Integrating energy recovery technologies helps reduce the carbon footprint and supports industrial sustainability goals.

Conclusion

Energy recovery in desalination is not only a technical necessity but also an economic and environmental strategy. It allows desalinated water production to be more efficient, sustainable, and competitive. For companies and industries looking to optimize water treatment processes, investing in energy recovery technologies is a decisive step toward more cost-effective and eco-friendly desalination, ensuring a reliable water supply with lower environmental impact.

Water conservation is one of today’s biggest challenges. Although planet Earth is covered by 70% water, only a small fraction is suitable for human consumption. With population growth and climate change, water scarcity is a reality affecting communities, industries, and ecosystems. The good news is that with simple actions you can make a big difference. Here are 5 simple things you can do to conserve water in your daily life.

1. Fix leaks and drips

A leaking faucet can waste up to 20 liters of water a day. Regularly checking pipes, taps, and toilets not only saves water but also lowers your water bill.

2. Use water-saving devices

Faucet aerators, low-flow toilets, and efficient showerheads are affordable tools that reduce consumption without sacrificing comfort. In many cities, these devices are key in efficient water use programs.

3. Optimize garden irrigation

Smart irrigation is essential for saving water. Watering early in the morning or late at night helps prevent evaporation. Consider installing drip irrigation systems, which deliver water directly to the roots. In addition, planting native or drought-resistant species reduces the need for constant watering.

4. Reuse water at home

The concept of water reuse can be applied at home in practical ways. For example, collecting washing machine water to clean floors or using rainwater for plants. These actions help reduce pressure on drinking water sources.

5. Change consumption habits

Simple actions like turning off the tap while brushing your teeth, washing the car with a bucket instead of a hose, or running full loads in the washing machine can save hundreds of liters each week.

Conclusion

Saving water doesn’t depend only on large infrastructures or advanced technologies—it starts with small changes at home and in industry. Adopting these sustainable practices helps protect a vital resource for our health, economy, and environment. Remember that every drop counts, and that responsible water use ensures a safer future for all.

Reverse osmosis (RO) is one of the most widely used technologies for water purification in industrial, municipal, and irrigation systems. However, the efficiency and lifespan of RO membranes largely depend on the chemistry applied during the water treatment process. Understanding how to protect these membranes is key to maximizing efficiency, reducing maintenance costs, and ensuring high-quality water.

Main Chemical Challenges for Membranes

RO membranes are sensitive to biofouling, mineral scaling, and chemical contamination. Feed water can contain calcium, magnesium, iron, manganese, silica, and organic compounds that, if uncontrolled, may deposit on the membrane surface. This reduces permeate flow, increases energy consumption, and can permanently damage the membrane.

Preventive Chemistry: Antiscalants and Cleaners

To protect membranes, antiscalant chemicals are used to inhibit the precipitation of salts and minerals, preventing scale formation. These products work by altering the crystallization of compounds that could adhere to the membrane, such as carbonates, sulfates, and silica.

In addition, biocides and disinfectants are essential to control biofouling caused by bacteria, algae, and fungi. Biofilm buildup on the membrane can drastically reduce performance and shorten its lifespan. Proper application of biocides ensures membranes maintain consistent high performance.

Periodic Cleaning: Key to Longevity

While preventive chemistry is vital, regular clean-in-place (CIP) procedures are equally important. Using specialized acidic, alkaline, or detergent solutions removes mineral deposits and accumulated organic contaminants, restoring membrane efficiency. The combination of prevention and cleaning ensures the system operates at peak capacity for years.

Conclusion

Protecting your reverse osmosis membranes is not just about physical maintenance; it’s a comprehensive chemical strategy. Understanding water chemistry, applying the right antiscalants, biocides, and cleaners, and regularly monitoring operational parameters allows you to extend membrane life, ensure water quality, and optimize your return on investment. Investing in membrane protection chemistry is investing in efficiency, savings, and reliability for your industrial processes.

Water reuse has become a strategic necessity for industries, municipal plants, and agricultural systems in response to increasing water scarcity. Among the most effective technologies for this purpose, reverse osmosis (RO) stands out for its ability to transform wastewater or process water into a safe and reusable resource.

What is Reverse Osmosis?

Reverse osmosis is an advanced filtration process that uses semipermeable membranes to remove dissolved salts, heavy metals, chemical contaminants, and microorganisms. Unlike other methods, RO ensures a high level of purification, making treated water compliant with industrial, agricultural, and municipal standards.

Benefits in Water Reuse

Reduction of freshwater consumption: By treating wastewater and reintroducing it into production processes, dependence on natural water sources is reduced, contributing to water sustainability.

Protection of equipment and processes: RO-treated water has low conductivity and is free of dissolved solids, protecting boilers, cooling towers, and irrigation systems from scaling and corrosion.

Regulatory compliance: Reverse osmosis ensures that reused water meets health and environmental standards, essential for the food, pharmaceutical, and cosmetic industries.

Cost optimization: Although the initial investment can be significant, RO reduces long-term expenses by lowering the consumption of potable water, chemicals, and maintenance needs.

Key Applications

Manufacturing industry: reuse of process and cooling water.

Agriculture: irrigation with treated water that preserves soil and plant health.

Municipalities: recycling wastewater for non-potable uses, such as cleaning and park irrigation.

Conclusion

The role of reverse osmosis in water reuse is essential to ensure efficiency, sustainability, and safety across different sectors. Implementing RO systems allows companies and communities to maximize the use of available water, protect the environment, and reduce operational costs. In a world where water is increasingly scarce, investing in water treatment and reuse technologies like reverse osmosis is not only a smart decision but also a commitment to the future of the planet.